Thinking Above the Noise

In the grand theater of cognition, the human minds at DPL Labs® can be envisioned not merely as a processing input but rather as an antenna actively receptive to an invisible yet omnipresent ether of conceptual information. This abstract explores the provocative hypothesis that the human brain, particularly in its role as an innovation engine for ideas, behaves as an organic antenna tuned and filtered to receive complex informational thoughts that correspond to technological constructs. By framing thought as an energetic phenomenon and the mind as an electromagnetic interface, we embark on an interdisciplinary journey blending neuroscience, systems engineering, and metaphysical speculation.

In the grand theater of cognition, the human minds at DPL Labs® can be envisioned not merely as a processing input but rather as an antenna actively receptive to an invisible yet omnipresent ether of conceptual information. This abstract explores the provocative hypothesis that the human brain, particularly in its role as an innovation engine for ideas, behaves as an organic antenna tuned and filtered to receive complex informational thoughts that correspond to technological constructs. By framing thought as an energetic phenomenon and the mind as an electromagnetic interface, we embark on an interdisciplinary journey blending neuroscience, systems engineering, and metaphysical speculation.

The analogy of the antenna is not purely metaphorical. Antennas, in their most fundamental sense, serve as transducers converting electromagnetic waves into electrical signals that can be interpreted, manipulated, and utilized. Likewise, the human brain receives and decodes external stimuli and abstract constructs into meaningful internal representations. The brain’s billions of neurons, structured as interconnected transmission lines exhibit behavior not unlike phased array antennas dynamically reconfigurable to respond to specific cognitive tasks or creative endeavors. Excepting these endeavors plays a sophisticated role in curing complex problems in this environment. It is called “Operating Outside the Box”

Operating Outside the Box

Where Only the Best Pass the Test

Operating Outside the Box When Testing Electronic Specifications

In the field of electronic engineering and testing, there exists a growing divide between the rigid application of standardized test protocols and the real-world conditions that electronic systems face when put into service. Traditional compliance testing methods, while indispensable for ensuring regulatory and interoperability requirements, can fall short in addressing the dynamic and increasingly complex behavior of modern electronics. As devices become more multifunctional, miniaturized, and performance-intensive, relying solely on in-the-box test criteria has shown significant limitations particularly when products must function reliably across unpredictable environments, under compound loads, and through mixed-signal interfaces.

Operating Outside the Box in this context refers to the practice of going beyond conventional compliance procedures to anticipate, capture, and correct performance degradations of failure modes that standard tests may miss. This method champions a more holistic, adaptive, and empirical approach to validation, one that acknowledges the shifting ground upon which specifications are literately built. We will explore the necessity, methodology, and implications of this practice in testing electronic specifications and highlight case studies where such thinking uncovers the root cause that may have otherwise gone unnoticed.

Standardized testing has been the backbone of product verification for decades. Protocols set by governing bodies such as IEEE, HDMI Licensing, USB-IF, and JEDEC define the operational limits and performance requirements of electronic systems and interfaces. While essential, these procedures are inherently conservative and defined by a set of fixed parameters intended to be repeatable and broadly applicable.

Yet today’s electronic devices must contend with increasingly multifaceted demands. A single interface may carry power, high-speed data, control signals, and even perform security functions. These multifunction transmission lines, such as those found in USB-C, HDMI 2.1, and DisplayPort complicate the signal environment with varying impedance, cross-domain interaction, and sometimes nonlinear loads. In such a setting, test engineers and product developers often encounter anomalies not anticipated by traditional test boundaries.

This dissonance has made one thing clear: the most critical failure modes are often found outside the rigidly defined test box. Thus, modern test engineering must include a deliberate effort to operate “outside the box” to build out real-world simulations, stress tests, a goal to intercepting defects before they reach the market.

Why Standard Test Specifications Sometimes Fall Short

There are a host of reasons why standardized testing procedures can fall short of expectations. Being standardized for so many new and complex system analysis makes the art of testing somewhat rudimentary without that spark of curiosity. Here are some examples:

- Narrow Operating Windows:

Specifications are often based on ideal conditions or limited worst-case scenarios. Real-world usage introduces variables such as fluctuating voltage rails, inconsistent grounding, environmental noise, and varying load profiles that extend beyond what may be defined in compliance criteria. - Multi-Signal Interference:

Mixed-signal systems are no longer a niche—they are standard. An HDMI cable for example carries high-speed differential video, low-speed I2C control signals, power delivery, Ethernet, and a static DC bias all under the same jacket. Standard tests rarely test these channels in concert or under active, simultaneous conditions with real world consumer products.

video, low-speed I2C control signals, power delivery, Ethernet, and a static DC bias all under the same jacket. Standard tests rarely test these channels in concert or under active, simultaneous conditions with real world consumer products. - Emerging Behaviors in High-Speed Systems:

Digital systems operating at 48 Gbps and beyond can exhibit phenomena like common-mode noise coupling, return loss imbalances, and jitter interactions that only appear at full operational loads stressing each DUT (Device Under Test). These, in some cases, can be invisible in static or loopback test environments. - Component Tolerances vs. Systemic Behavior:

Tightly spec’d components often fail when integrated into systems due to accumulation of tolerances, parasitic behavior, installation variances, or unexpected interaction across elements. System-level validation, which falls outside many spec-driven test routines, is vital to catching these subtleties.

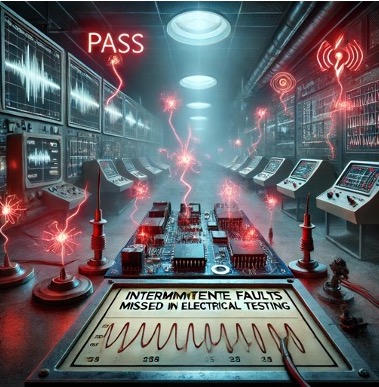

The Philosophy of Testing Outside the Box

Operating outside the box means reimagining the test process not as a simple pass/fail gatekeeper, but as a forensic and exploratory instrument. This approach redefines the role of the operator not just as a verifier of specification compliance, but as an investigator uncovering hidden behaviors and vulnerabilities. Each test procedure is deliberately infused with known stressors and weaknesses, intentionally provoking failure in the Device Under Test (DUT). This proactive strategy goes beyond conventional validation by incorporating external influences such as marginal power supply conditions and induced noise that might otherwise be dismissed as anomalies of poor design or environmental interference. Rather than settling for a test that passes under ideal conditions, this methodology reveals how systems behave under realistic, often adverse scenarios, that can lead to more robust and reliable designs.

Case Study Example: HDMI 2.0 Failures in Field Deployment

A compelling example emerges from the HDMI 2.0 ecosystem, where certified cables and devices, despite passing all standard compliance tests, began to exhibit failures in real-world installations. Field reports revealed symptoms such as video dropouts, handshake interruptions, and erratic HDR performance. Deeper forensic analysis uncovered several critical flaws that remained invisible during conventional testing:

- Voltage sag on active TMDS and FRL lanes due to supply line starvation led to intermittent data corruption, even though equalization (EQ) settings passed specification-defined margin testing.

- Timing violations on the DDC (I²C) channel triggered handshake failures with certain AV receivers, particularly during simultaneous EDID polling and HDCP rekeying events—conditions not simulated in standard test sequences.

- Excessive power draw from active devices during startup sequences exceeded the passive current-carrying capacity of the source’s +5V supply, collapsing the voltage rail and disrupting video transmission entirely.

These failures only surfaced under holistic, system-level testing that introduced real-world stress conditions, full protocol activation, and cable interaction modeling. Notably, in every case, the products in question were fully compliant with the HDMI 2.0 specification. This disconnect underscores the limitations of traditional pass/fail compliance methods and highlights the importance of testing outside the box where the focus shifts to uncovering system-level vulnerabilities that are otherwise hidden under idealized conditions.

Out-of-the-Box Tools and Techniques

Many of our out-of-the-box tools and techniques are rooted in traditional test equipment and procedures. What sets them apart is not the tools themselves, but how they are applied. Here are several of the more widely used and innovative approaches:

- Advanced Signal Integrity Analysis

Techniques like eye diagram generation, bit error rate (BER) analysis, jitter decomposition, and impedance profiling are essential for identifying time-domain issues that standard signal generators often miss. - Power Emulation and Monitoring

Power emulators can replicate source/sink roles and simulate challenging scenarios such as brownouts, reverse current draw, and voltage sags. These tests help validate system resilience under atypical power conditions. - Environmental Simulation

Equipment like thermal chambers, vibration platforms, and EMI test environments expose vulnerabilities tied to physical and environmental stress. Weak solder joints or insufficient decoupling are often first revealed under these conditions. - Custom Test Harnesses

When off-the-shelf tools are too restrictive, engineers design custom test fixtures to provide access to critical test points, enable fault injection, and allow dynamic system reconfiguration, ideal for capturing edge-case behaviors.

Challenges and Considerations

While out-of-the-box testing yields immense value, it carries its own demands:

- Cost and Time: These tests often require specialized equipment, extended cycles, and trained personnel.

- Risk of Over-Engineering: Chasing every potential failure path may lead to bloated designs and cost overruns if not carefully managed.

- Interdepartmental Alignment: Product management, marketing, and QA teams must support this approach or risk friction over delayed schedules or unexpected test failures.

- Standardization Gap: Since out-of-box tests are not uniformly defined, communicating failures or risks to external stakeholders may require significant effort in documentation and explanation.

The Future of Test Engineering

The exponential complexity of modern electronics demands an equally sophisticated and creative approach to testing. Engineers can no longer afford to think only inside the compliance box. The need to simulate real-world conditions, capture nuanced failures, and proactively investigate abnormal behavior is not just a best practice, it’s a necessity.

As interfaces merge power and data, and as performance thresholds rise, the line between pass and fail becomes increasingly blurred. Test operators must shift from checklists to curiosity, from protocol execution to problem prediction.

In this spirit, Operating Outside the Box is not an abandonment of standards but an evolution of them. It reflects a commitment to excellence, to robustness, and to a user experience that extends beyond the lab into the real world, where perfection is desirable and reliability is everything.