Interoperability

From Controlled Environments to Uncontrolled Reality

The rapid surge of consumer electronics flooding the market has created a tangled landscape of interoperability challenges. In the race to meet demand and outpace competitors, some manufacturers have introduced products not necessarily adhering to the stringent performance limits required to bring the majority of mixed signal transmissions across a truly “fully functional” finish  line. This erosion of precision and compliance often produces devices that seem to perform adequately in isolated testing yet falter when integrated into diverse system environments, particularly alongside more advanced, high-performance components, ultimately compromising seamless operation and long-term reliably.

line. This erosion of precision and compliance often produces devices that seem to perform adequately in isolated testing yet falter when integrated into diverse system environments, particularly alongside more advanced, high-performance components, ultimately compromising seamless operation and long-term reliably.

This shift has compelled test facilities to broaden their processes and procedures, incorporating a comprehensive interoperability testing stage that has now become a cornerstone in validating modern electronic systems. This is especially critical in sectors such as consumer electronics, networking, and audiovisual integration, where a multitude of devices and protocols must operate together flawlessly.

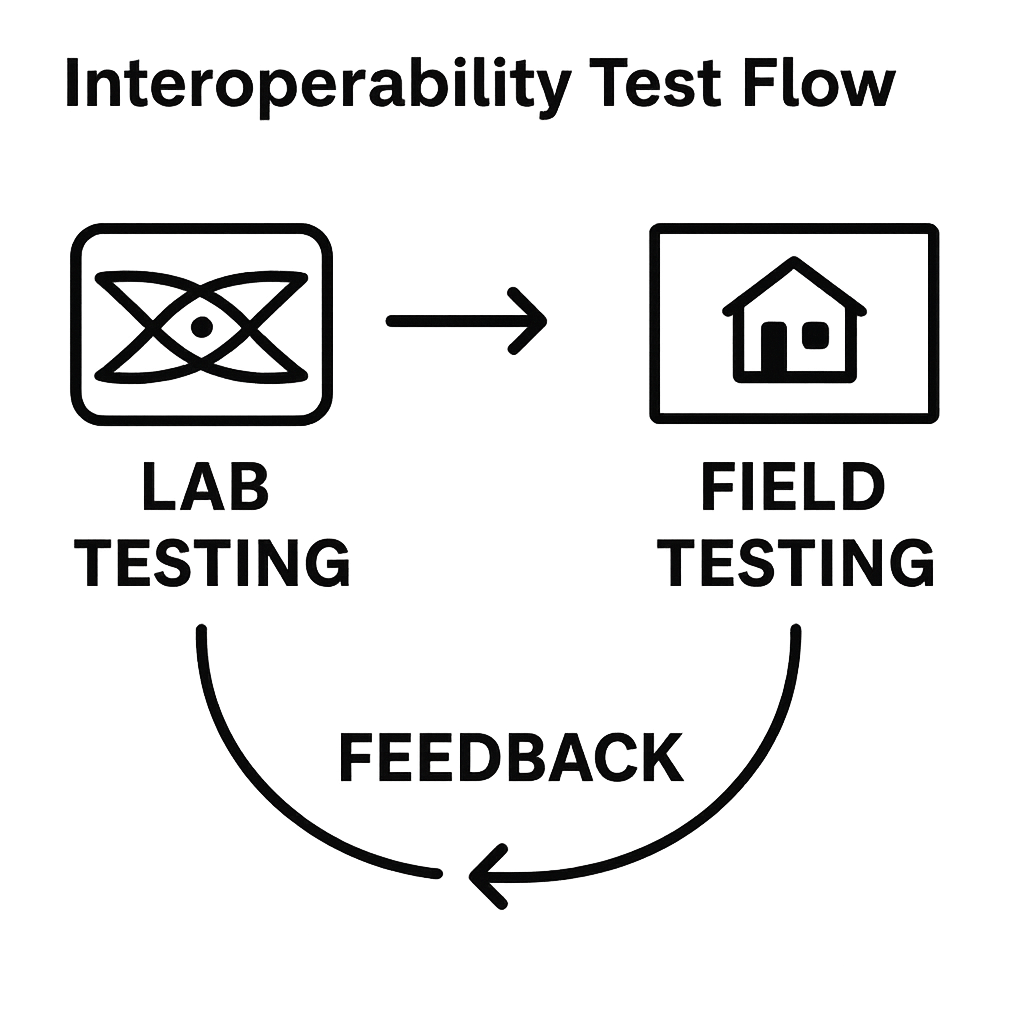

But in practice, achieving this requires a balance of controlled laboratory instrumentation testing and real-world operational validation. Each approach targets different failure modes, and together they form a comprehensive assurance strategy.

Laboratory-Based Instrumentation Testing

Test instrumentation provides a controlled environment where variables can be precisely measured, manipulated, and repeated. Using dedicated test equipment, such as bit error rate testers (BERTs), eye pattern analyzers, signal integrity oscilloscopes, protocol analyzers, and compliance testers, engineers can evaluate a device’s performance against strict protocol specifications.

In the context of HDMI, DisplayPort, USB, or similar high-speed mixed signal interfaces, instrumentation allows for:

• Quantitative measurements such as rise/fall times, jitter margins, crosstalk levels, and noise immunity.

• Stress testing by introducing impairments (attenuation, skew, inter-symbol interference, or EMI) beyond nominal operational limits to reveal vulnerabilities.

• Repeatability in failure analysis, where identical conditions can be re-applied to verify fixes.

• Standards compliance verification, ensuring signals and protocols match the precise tolerances defined by governing bodies.

A key advantage to instrumentation is isolation, specific parameters can be stressed without the influence of unrelated variables. For instance, a 12 Gbps per-channel HDMI link can be evaluated purely for jitter tolerance without interference from unrelated firmware behavior.

However, instrumentation tests are by nature idealized: the device under test (DUT) interacts with precise, calibrated signals that rarely reflect the variability and the chaos it can put into a customer’s home or office environment.

Real-Life Operational Testing

Once a product passes lab-based evaluation, it must be proven in operational environments where variables multiply and unpredictability rules. Real-life interoperability testing places the DUT into scenarios with commercially available devices, cables, and environmental factors, elements that instrumentation cannot fully simulate.

Examples include:

• Connecting an HDMI cables to a wide range of source and sink devices from different manufacturers and production years.

• Using both premium and budget electronic products.

• Operating the system alongside real-world electromagnetic interference sources like Wi-Fi routers, computer related systems, or switching power supplies.

• Introducing firmware quirks from third-party devices that still technically meet the specification but exhibit edge-case timing, signaling behavior or system grounding.

Operational testing often uncovers hidden interoperability failures, those that pass in the lab but surface in customer hands. These could be due to subtle protocol interpretation differences, signal margin erosion from long cable runs, or borderline compliance in one device interacting with borderline compliance in another.

Importantly, real-world testing helps assess user experience: ease of setup, resilience to hot-plug events, recovery after power cycles, and consistent behavior across various brands and generations.

Neither instrumentation nor real-world testing is sufficient on its own. Laboratory tests confirm that a design meets baseline compliance and margin requirements, providing confidence that it should work with other compliant devices. Real-world testing validates that it does work, even under the unpredictable conditions of actual use.

An effective interoperability testing strategy follows this pattern:

1. Instrumented Validation – Confirm compliance, performance margins, and immunity to stressed conditions.

2. Operational Validation – Expose the DUT to a matrix of real devices, cables, environments, and usage patterns.

2. Operational Validation – Expose the DUT to a matrix of real devices, cables, environments, and usage patterns.

3. Feedback Loop – Issues found in operational testing are reproduced under instrumentation to identify and resolve root causes.

4. Iterative Refinement – Adjust designs, firmware, or tolerances, then repeat both test phases.

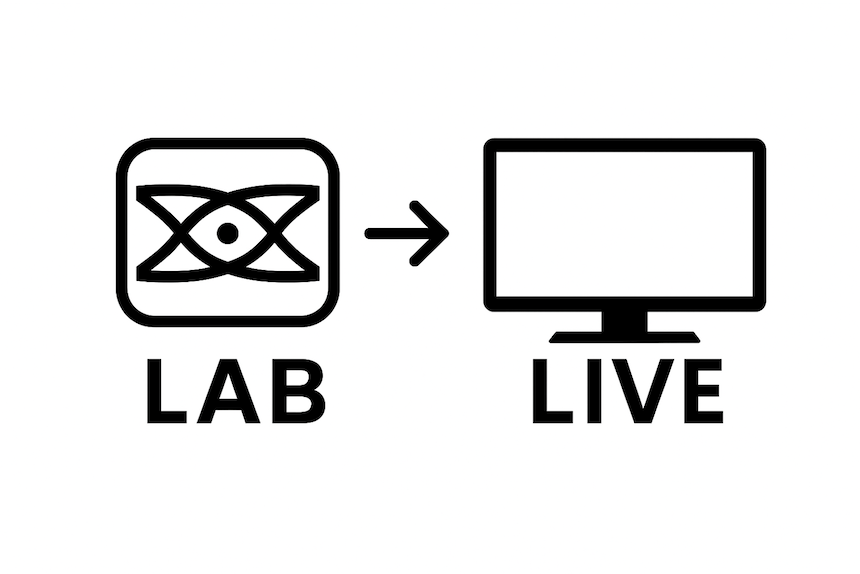

This combined approach not only reduces the risk of field failures, but also boosts customer satisfaction, lowers product returns, and reinforces brand trust. Over time, DPL Labs® has identified recurring anomalies through its testing R&D and, in response, has developed an additional procedure dedicated specifically to interoperability issues. This procedure is now a formal part of the DPL Labs® 48G Enhanced Reference Standard Platform. Known as  “Lab to Live™,” this expanded testing methodology is designed to bridge the gap between controlled laboratory validation and unpredictable real-world operation, ensuring products perform seamlessly in both environments.

“Lab to Live™,” this expanded testing methodology is designed to bridge the gap between controlled laboratory validation and unpredictable real-world operation, ensuring products perform seamlessly in both environments.