Video Technology Unfolds

at

CEDIA 2025

Every fall, the consumer electronics industry gathers for a trade event (CEDIA) that has become a benchmark for innovation in home entertainment and system integration. Once considered a niche exhibition for installers, integrators, and technology vendors, this annual event has grown into a platform where the most forward-looking breakthroughs in consumer technology are unveiled. This year, as in many before, video once again took center stage, but with a depth and maturity that signals not just incremental progress, but a transformation of the ecosystem.

Breaking Boundaries: Screen Size Without Limits

The narrative surrounding display technology has shifted dramatically in just a few short years. It was not long ago that the question most buyers and integrators would asked was: What’s the largest screen can I buy? Today, thanks to modular Micro-LED panels and advanced video wall systems, that question has been replaced with: How large of a screen do you want?

This is not mere wordplay. The technology underlying these screens has enabled virtually unlimited scalability. Micro-LED modular panels can be tiled seamlessly, producing displays that can span entire living room walls or stretch across the width of commercial lobbies. Unlike legacy projection systems or early flat panels, these displays lose little to no resolution or brightness as they scale.

Whether the end goal is a modest home cinema or a massive 20-foot-wide wall, the underlying building blocks remain consistent in quality and performance. These refinements address one of the historic challenges of large-scale LED displays: ensuring that hundreds of modular panels can operate as a singular visual canvas. One key player that provides these huge dynamic changes are the LED’s themselves.

COB vs. SMD LEDs in Video Wall Panels

These types of displays are built from small modular panels, each containing thousands of light-emitting diodes. The way these diodes are packaged and arranged determines not only picture quality but also the cost, durability, and long-term reliability of the system. Two dominant packaging technologies, COB (Chip on Board) and SMD (Surface Mounted Device), offer different advantages and limitations, and their use in video wall construction continues to shape the direction of the industry.

COB Technology

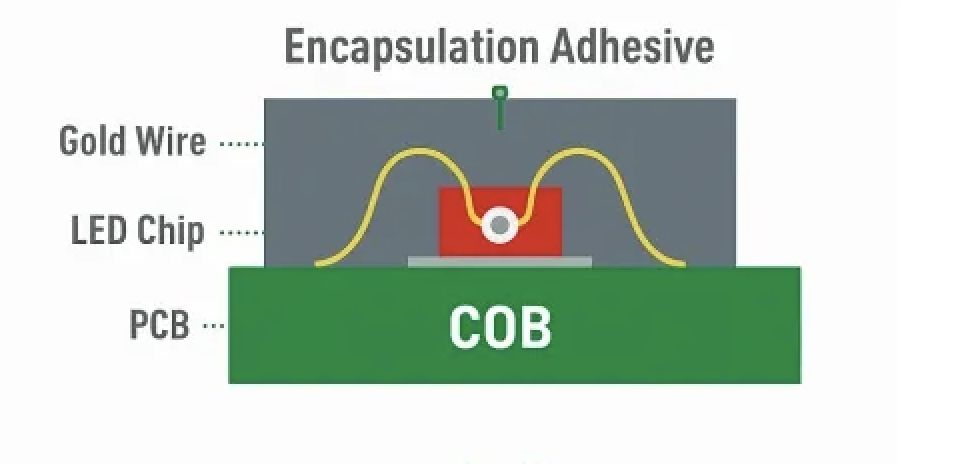

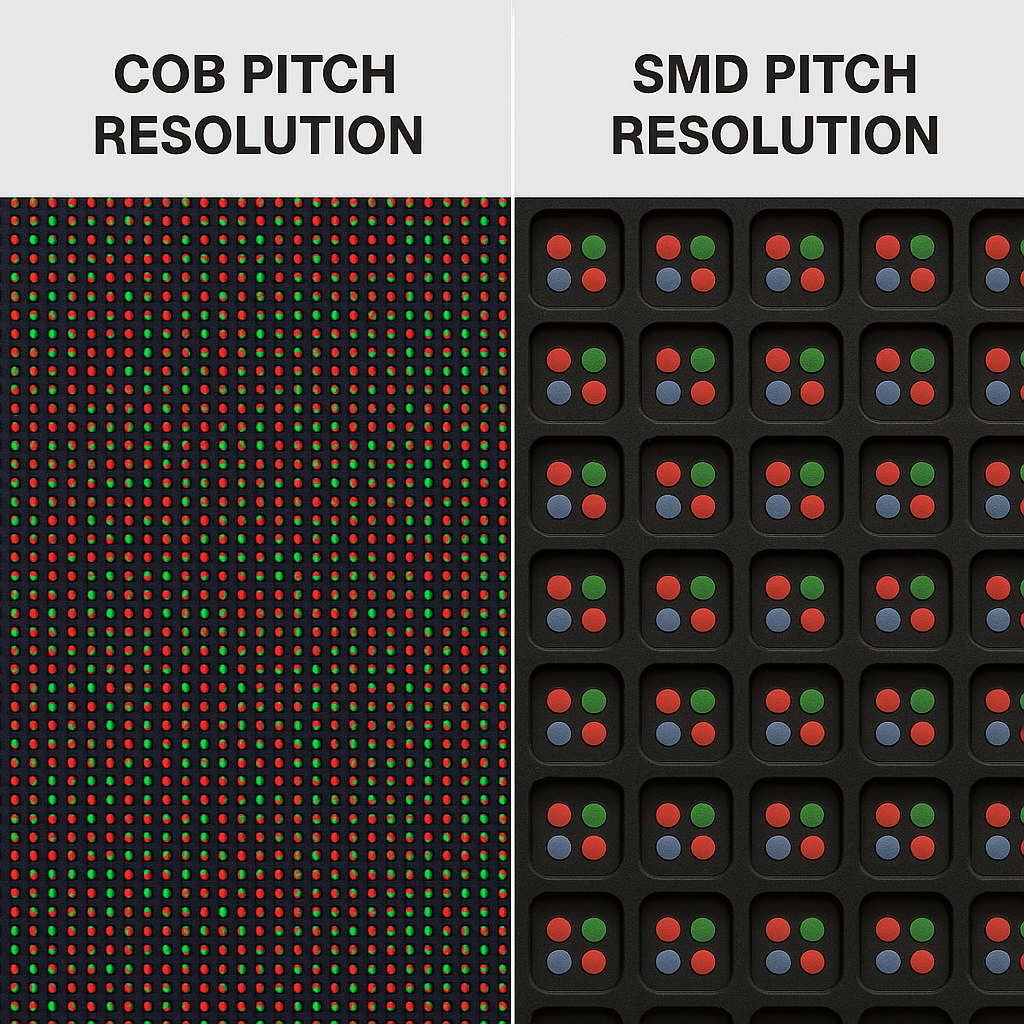

Chip on Board, or COB, is a method of mounting multiple bare LED dies directly onto a substrate, typically a printed circuit board or ceramic material, before sealing them with a thin protective layer of epoxy or phosphor. This approach eliminates the need for each LED to have its own package, which allows for a much tighter arrangement of chips. The result is a technology that can deliver extremely fine pixel pitches, in some cases as low as .7 millimeter.

The advantages of COB in video wall applications are clear. With no bulky packaging, chips can be placed in close proximity, enabling high-density displays capable of 4K or even 8K resolution on relatively modest wall sizes. The encapsulation process produces smoother and more uniform light output, reducing visible pixel boundaries and creating a softer image with fewer artifacts such as the “screen door” effect. Because the chips are protected under resin, COB panels are more durable and resistant to accidental impact, dust, or moisture, making them suitable for environments where people may interact with or come into close contact with the display. The direct mounting of chips also improves heat dissipation, which enhances efficiency and extends the lifespan of the diodes.

However, COB does present challenges. If a single LED chip or sub-pixel fails, repair is difficult, as the encapsulation layer prevents easy replacement. Often, the entire module must be swapped, which increases maintenance costs over time. Manufacturing is more complex and costly due to the precision bonding and encapsulation required, meaning that COB walls typically command a premium price. While COB systems exist, color control can be less flexible than with discrete SMD packages, making color tuning more difficult in some implementations.

SMD Technology

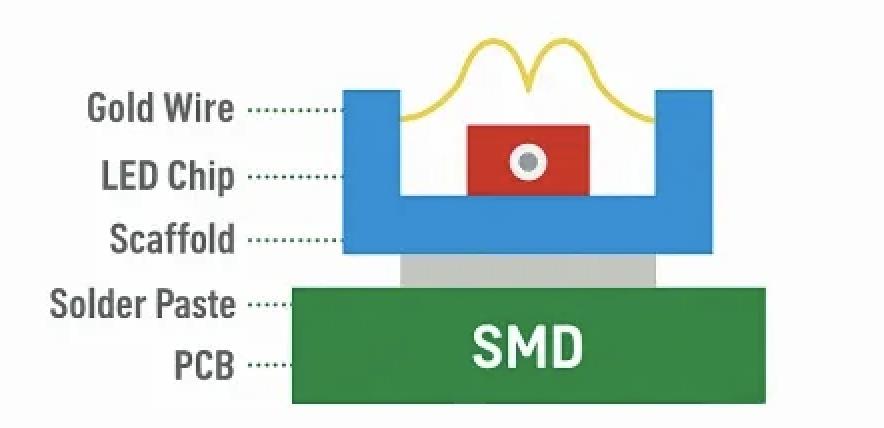

Surface Mounted Device LEDs represent a more traditional and widely used packaging method. In this approach, each LED chip is enclosed in a small package, which is then soldered directly onto a printed circuit board. The package can contain a single diode or, in many cases, all three primary colors, red, green, and blue, within a single housing. These packaged diodes are then arranged in a regular matrix across each panel.

SMD remains popular in video wall construction because of its versatility and cost efficiency. Standardized package sizes allow manufacturers to design displays across a wide range of pitches, brightness levels, and costs, making it adaptable for everything from large commercial signage to indoor fine-pitch walls.  The maturity of SMD production processes ensures economies of scale, which drives down initial purchase prices compared to COB. Color performance is another strength: because discrete red, green, and blue dies are combined within each package, manufacturers can finely tune color mixing, providing excellent accuracy and a wide color gamut. Maintenance is also simpler, since a single failed diode can often be replaced individually without discarding the entire module.

The maturity of SMD production processes ensures economies of scale, which drives down initial purchase prices compared to COB. Color performance is another strength: because discrete red, green, and blue dies are combined within each package, manufacturers can finely tune color mixing, providing excellent accuracy and a wide color gamut. Maintenance is also simpler, since a single failed diode can often be replaced individually without discarding the entire module.

Nonetheless, SMD has its drawbacks. The physical size of each package limits how close LEDs can be mounted, which means there is a practical lower limit to how fine the pixel pitch can be. While modern SMD walls can achieve 1-millimeter pitches, COB technology surpasses this when extreme density is required. The protruding nature of the SMD packaged diodes makes them more vulnerable to physical damage, and heat dissipation is less efficient than COB, since thermal energy must travel through the packaging before reaching the circuit board.

When viewed side by side, the distinctions between COB and SMD become clear. COB delivers higher pixel densities, superior uniformity, and greater physical durability, but at the expense of higher manufacturing costs and more complex repair procedures. SMD offers a balance of affordability, strong color performance, and simpler maintenance, but it faces limitations in pixel pitch and mechanical robustness.

The decision to use COB or SMD in a video wall depends on the specific requirements of the project. COB is best suited for environments where ultra-fine pixel pitch, seamless image quality, and durability are essential, such as boardrooms, broadcast studios, or premium residential theaters. SMD, on the other hand, continues to dominate large-scale installations where cost efficiency, scalability, and flexible color performance are more important, such as stadiums, outdoor advertising, and commercial signage.

Both technologies will remain relevant for years to come. COB is driving the future of high-density, premium video walls that can be viewed at close range without visible pixelation, while SMD continues to provide a proven, versatile foundation for large-format displays. Together, they ensure that video walls will remain one of the most dynamic and adaptable display platforms available in the marketplace.

These advancements bring with them a new set of rules. Resolution no longer deteriorates as with devices in the past. Black levels remain deep and uniform, and bezel-free designed panels almost eliminates the visual seams that once betrayed multi-panel configurations. The psychological shift is clear: the “largest possible display” is no longer limited by the constraints of a single manufactured panel, but by the imagination of the installer, state of the art panel control systems and the budget of the client.

Bezel-Free vs. Bezel-Type LED Panels: A Comparative View

With all the advancements we have discussed in LED panel technology, one of the most defining aspects remains how individual panels connect to form a larger display. A key distinction lies in whether the panels are built with visible bezels or designed to be bezel-free. Bezels, the borders framing each panel, can interrupt the continuity of an image or, in some cases, provide structural advantages. Over the past two decades, however, the industry has steadily moved away from bezel-type systems toward bezel-free designs, dramatically improving the visual impact and functionality of video walls.

Historical Perspective

In the early 2000s, tiled video walls were dominated by LCD panels. These panels were durable and cost-effective, but each one carried a thick bezel around its perimeter. When combined to form larger displays, the black borders created a distracting grid pattern that segmented the image. Even as manufacturers worked to reduce bezel widths, from 20 mm to under 5 mm, the seams were still visible, particularly in applications like advertising or broadcast studios where visual continuity mattered most.

LED technology began to change this paradigm. Early LED walls also had visible housing borders and coarse pixel pitches, limiting them to outdoor billboards and stadium displays where viewers were far away. At those distances, seams mattered less, but close viewing revealed the modular structure. The pursuit of finer pixel pitches and seamless edges led to the development of bezel-free LED panels, which extended the active LED area almost to the panel’s edge, effectively removing visual interruptions.

Bezel-Type LED Panels

Bezel-type panels remain in use today in certain contexts. The visible border provides protection for the screen’s edges, improves mechanical stability, and simplifies handling. For control rooms, where the priority is displaying discrete information feeds rather than a single continuous image, bezels are less of a drawback. Bezel-type systems are also less costly to manufacture and install, making them attractive for budget-conscious projects.

The drawback is that when tiled, the bezels interrupt the content with visible lines. This creates a segmented appearance that detracts from immersion. For applications demanding cinematic or high-impact visuals, such as retail showcases or luxury entertainment, this is a major disadvantage.

Bezel-Free LED Panels

Bezel-free designs address these shortcomings by eliminating visible borders at the seams. By pushing active LEDs to the panel’s edge, manufacturers can produce video walls that appear as one continuous canvas. From the intended viewing distance, seams disappear, allowing content to flow seamlessly across the surface.

This design requires precise engineering. Panels must align with tight tolerances, and pixel mapping has to be exact to prevent visible misregistration. Advanced packaging methods such as COB (Chip on Board) enhance the bezel-free effect further by creating smoother module surfaces and improving edge durability. The result is a more immersive experience, suitable for broadcast studios, control centers with fine visualization needs, and premium environments like boardrooms or high-end residential theaters.

Control System Processors For Video Wall Solutions

The real strength of a video wall system rests not just in the LED panels themselves but in the Control Processors (CP) that drive them. While the panels provide the raw surface of pixels, the CP determines how those pixels are used, making it possible to combine multiple content sources, scale them to the size of the wall, and position them anywhere on the screen with precision.

Early video wall designs were limited to a single signal stretched across all panels. That worked for basic signage but could not meet the needs of control rooms, broadcasters, or retailers where multiple streams must be viewed at once. Modern CP’s solve this by allowing simultaneous display of live video, data dashboards, pre-recorded clips, or conferencing feeds, all arranged in real time.

With the adoption of Chip on Board LED technology, this capability is even more significant. COB panels deliver extremely fine pixel pitch, improved durability, and seamless, bezel-free surfaces, creating the appearance of one continuous screen. For the controller, this demands pixel-level management and precise scaling so that multiple sources can be positioned without visible artifacts or misalignments. The seamless nature of COB emphasizes any error, which makes the role of the CP more critical than ever.

The defining role of modern video wall controllers is no longer limited to scaling one image. Their real value lies in transforming the wall into a dynamic, multi-source canvas where content can be positioned and managed with freedom. Combined with the seamless surface and fine pitch of COB LED technology, these systems represent the next stage in large-scale display innovation.

Video Splicing and Content Flexibility

Another highlight at the show was the growing use of video splicing, where processors combine or “splice” multiple content streams into a single, cohesive canvas. This capability is particularly important with fine-pitch LED walls, where clients often want to display multiple sources simultaneously, live video feeds, presentations, streamed content, or data visualizations, all arranged dynamically across one large screen similar to having 3 football games playing on one screen at once.

Modern CP’s demonstrated the ability to not only split the wall into zones but also to splice video in real time without visible seams or timing errors. Unlike traditional picture-in-picture, splicing involves frame-accurate stitching across outputs, ensuring that each window maintains synchronization with its source while still appearing integrated into the whole display.

Integrators saw examples of sports bars showing multiple live feeds seamlessly tiled together, as well as corporate environments where video conferencing windows were spliced alongside presentations and real-time analytics dashboards. The critical advancement here is that splicing no longer requires massive external hardware arrays; it is now handled natively within compact processors that manage scaling, synchronization, and HDR consistency on the fly.

For commercial and residential projects alike, video splicing opens new design opportunities. In a luxury home theater, an LED wall might be divided so the family can watch a film, monitor a game, and follow a news ticker simultaneously, all in perfect sync, without visible lag or mismatched color balance between segments. This flexibility demonstrates how processing power is not only about enhancing images but also about empowering new modes of content consumption.

Advances in Signal Processing

In the evolving landscape of video technology, the sophistication of signal processing has become one of the most influential forces shaping the quality and consistency of the viewing experience. Displays continue to grow larger, resolutions climb higher, and formats become more diverse, but none of this progress is meaningful without robust processing to ensure that the content makes its journey from source to screen intact, optimized, and tailored for the display at hand. At the CEDIA 2025 event, advances in signal processing commanded attention, demonstrating that the intelligence behind the scenes is just as important as the visible brilliance of LED walls, projectors, and OLED panels.

The Expanding Role of Video Processors

Traditionally, video processors were tasked with a relatively simple mandate: scale an image to fit the display or convert between formats. In today’s environment, those tasks are only the foundation. Modern processors integrate sophisticated algorithms that dynamically refine every frame. Tone mapping ensures that content originally mastered for one display standard translates accurately to another. Frame interpolation reduces motion blur without introducing artifacts. Real-time HDR optimization analyzes each scene and adjusts parameters to match both the source intent and the display’s capability.

One of the most talked-about examples at the event was the madVR Envy platform.  Already well regarded in the enthusiast and integrator communities, Envy’s latest generation emphasized tone mapping that ensures that content mastered from an ideal super-bright 10,000 nits display still translates accurately to today’s actual projectors and TVs which have far lower peak luminance capabilities along with precision scaling algorithms that keep 4K and 8K images razor-sharp without over-processing. For home theater clients seeking reference-grade reproduction, it demonstrated how modern processing can transform even difficult HDR material into a balanced, lifelike presentation.

Already well regarded in the enthusiast and integrator communities, Envy’s latest generation emphasized tone mapping that ensures that content mastered from an ideal super-bright 10,000 nits display still translates accurately to today’s actual projectors and TVs which have far lower peak luminance capabilities along with precision scaling algorithms that keep 4K and 8K images razor-sharp without over-processing. For home theater clients seeking reference-grade reproduction, it demonstrated how modern processing can transform even difficult HDR material into a balanced, lifelike presentation.

Looking Ahead

The innovations displayed suggest that signal processing will remain at the core of the AV ecosystem for years to come. As display technologies push further into 8K and beyond, and as active optical transmission and fiber systems extend the range of installations, the processor’s role as both translator and guardian of signal integrity will only grow.

Breaking Barriers With

Long-Distance High-Speed Cabling

While large-format displays and sophisticated external video signal processors represent the visible end of system evolution, connectivity defines whether those displays can perform as intended. High-speed interconnects have long constrained system design. As signaling rates increased from HD to 4K and now to 8K, copper cabling faced unavoidable impairments such as insertion loss, return loss, inter-pair skew, and crosstalk. These effects degrade the eye opening, increase jitter, and ultimately reduce system margin, particularly over distance.

DPL Labs’ evaluation framework extends well beyond nominal compliance testing by subjecting cabling and devices to stressed eye conditions, long-haul attenuation profiles, and equalization stress scenarios. Key measurements include jitter tolerance, S-parameter analysis, bit error rate (BER) under randomized stress loads, and active monitoring of eye diagram collapse across varying channel lengths.

Through these proprietary methodologies, DPL Labs has been able to isolate root-cause anomalies behind interoperability failure, often invisible under standard test regimes. This work has enabled improved power management schemes, refined equalization strategies, and higher throughput stability, addressing the long-standing bottlenecks of high-speed cabling in real-world system environments.

This year, hybrid optical fiber products have shown that those limitations can be overcome. A few manufacturers demonstrated passing these new operating limits providing cables with reliable performance spanning 100 meters, carrying full 48 Gbps HDMI signals without degradation. Even more impressive and expensive were all-fiber solutions, which can extend even further while reducing bulk and simplifying installation. For integrators, this opens the door to entirely new design possibilities. A central rack can now feed pristine 8K content to displays and projectors located hundreds of feet away, something that would have been impossible or unreliable just a few years ago.

A few manufacturers demonstrated passing these new operating limits providing cables with reliable performance spanning 100 meters, carrying full 48 Gbps HDMI signals without degradation. Even more impressive and expensive were all-fiber solutions, which can extend even further while reducing bulk and simplifying installation. For integrators, this opens the door to entirely new design possibilities. A central rack can now feed pristine 8K content to displays and projectors located hundreds of feet away, something that would have been impossible or unreliable just a few years ago.

Advancements in this field have been rapid, driven by both consumer and professional demand. Early active optical cables often required external power injectors and were fragile in construction. Today’s AOC’s (Active Optical Cable) have improved dramatically with HDMI fiber solutions employ improved laser diodes, low-power conversion electronics, and robust shielding, all of which allow improved plug-and-play operation and better reliability. Connector housings have been improved and able to fit better into recessed panels. These changes have transformed AOC HDMI fiber from a niche solution into a mainstream tool for integrators.

The implications ripple through both residential and commercial applications. Large homes with distributed video systems, high-end sports bars with dozens of screens, and auditoriums with enormous LED backdrops can now all be designed with confidence that distance will not compromise quality. The age-old struggle between distance and bandwidth is giving way to a new expectation: video, no matter how advanced and with the correct products can work everywhere in the building.

The Marriage of Scale and Reliability

Perhaps the most important theme of the show was the marriage between scale and reliability. Big screens are not new. Long cables are not new. Advanced processors are not new. What is new is that all three have matured to the point where they can coexist without constant compromise or risk.

Integrators can now design a home theater with a 12-foot-wide LED wall, feed it with fiber optics from a centralized rack, and rely on video processors to manage switching, scaling, and HDR tone mapping, all while maintaining performance that is indistinguishable from a short-run reference setup. For commercial projects, the scalability is even greater: 8K video walls for corporate lobbies, digital signage spanning entire atriums, and immersive environments powered by synchronized projectors and LED modules.

This reliability is a milestone. In the past, pushing the boundaries of video technology often meant accepting fragility, systems that worked only under perfect conditions, that degraded over time, or that failed unpredictably in the field. The shift on display this year is that companies are building solutions not just for the laboratory or the showroom, but for real-world environments where uptime, consistency, and ease of service are paramount.

Scanning the Past and Defining the Future

8K Association Defines the Future

At CEDIA 2025 the 8K Association made a major push to show that 8K has evolved into a full ecosystem rather than just another resolution step. Their presence was anchored by the 8K Pavilion, that gathered more than a  dozen member and partner companies, from display makers like Epson, JVC, and Samsung to content platforms such as Kaleidescape and studios like IMAX, Warner Bros and MGM. The Pavilion was deliberately positioned as a hub where integrators, dealers, and technology partners could see the full chain of 8K in action, from content creation to delivery and playback.

dozen member and partner companies, from display makers like Epson, JVC, and Samsung to content platforms such as Kaleidescape and studios like IMAX, Warner Bros and MGM. The Pavilion was deliberately positioned as a hub where integrators, dealers, and technology partners could see the full chain of 8K in action, from content creation to delivery and playback.

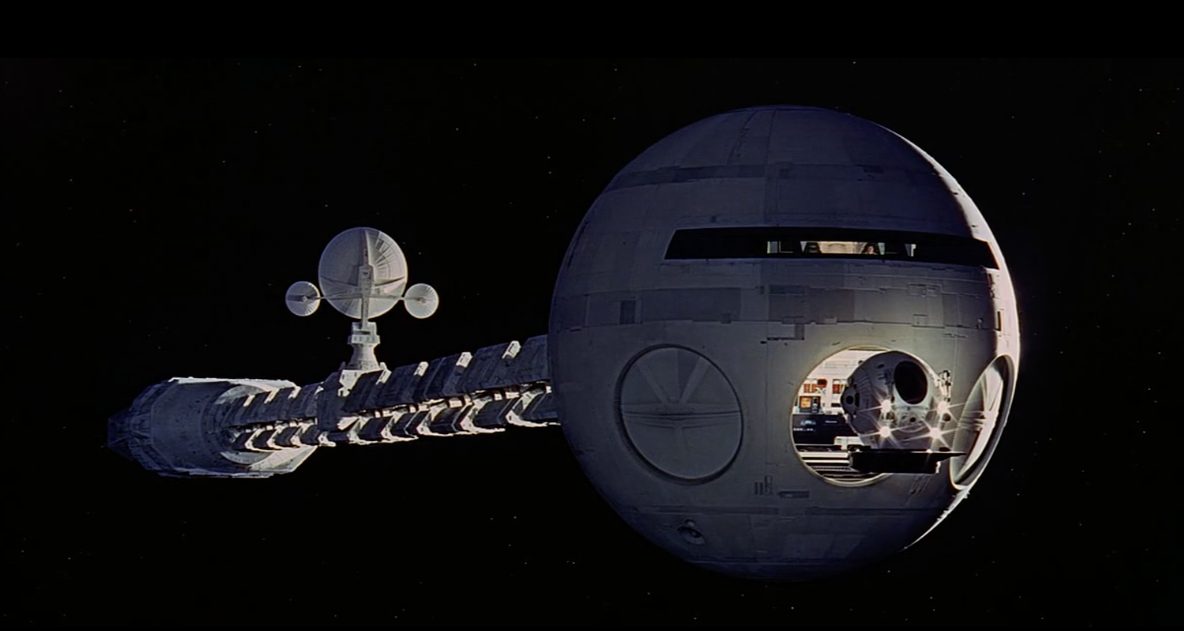

One of the most compelling elements was the content itself. Visitors saw newly transferred and scanned material from 35mm and 65mm film, including reels from classics such as 2001: A Space Odyssey and West Side Story, alongside native 8K footage from IMAX, Savage Studios, and The Explorers.

Beyond demonstrations, the 8K Association used the event to unveil a broader communications strategy. They emphasized not only resolution but also the role of artificial intelligence, processing, and immersive screen sizes in shaping what they described as the “giant screen era” of home cinema. Their Technical Work Group updated progress on standards and certification, and they introduced a new specification for wireless audio delivery called ACM (Audio Connection for Multi-Devices), which allows TVs to stream compressed or uncompressed audio over Wi-Fi to soundbars and other playback devices. This kind of interoperability message was meant to reassure integrators that 8K is being built with a practical, whole-system approach.

The impact of their participation was significant because it brought together content creators, technology manufacturers, and integration companies under one roof at an international consumer electronics event. For those who may have seen 8K as abstract or premature in previous years, the 8K Pavilion presented a very different picture: a living, working ecosystem ready for deployment.

Paving the Way for the Next Decade

Looking ahead, the trends highlighted at this year’s trade show suggest a trajectory of continued growth and convergence. Displays will keep getting larger and sharper as Micro-LED fabrication improves. Fiber optics will become the default medium for high-bandwidth video, just as it already is in telecommunications. Video processors will gain even more intelligence, likely incorporating AI-driven calibration and dynamic optimization to further reduce the human labor required to set up and maintain complex systems.

Another emerging dimension is sustainability. As LED walls continue to grow in popularity replacing projectors in more applications, power efficiency and thermal management will become front-line engineering challenges. Likewise, as fiber optics replace copper, the industry will grapple with recycling and environmental impact of glass versus metal cabling. These are conversations that are beginning now and will shape design choices for years to come.>